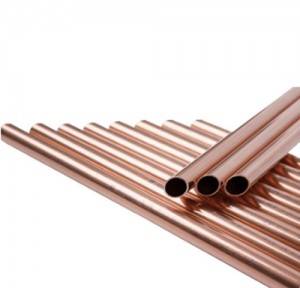

brass tube

Brass Pipe Copper Pipe C51900 Tin Bronze pipe of copper alloy

| Material | Pure Copper, Brass, Bronze and special copper alloy | |||||||||

| Construction | Tube(Pipe), Wire, Ingot, Rod(Bar), Plate, Strip, Foil or Customized | |||||||||

| Shape | Round, Square, Flat, Hexagon, Oval,Half-round or Customized | |||||||||

| Dimension | Standard or Customized | |||||||||

| Standard | GB/T,JIS,ASTM, ISO, DIN, BS, NF etc. | |||||||||

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard. | |||||||||

| Place of origin | Shanghai, China | |||||||||

| Package | Plastic film + Wooden case or as per customer requirement | |||||||||

| Surface | Polished,bright,oiled,hair line,brush,mirror,or as required | |||||||||

| MOQ | Negotiable | |||||||||

| Deliver time | According to order's quantity. | |||||||||

| Shipment | By sea, by air, DHL, UPS, FedEx etc. or as required | |||||||||

| Application | Electric light industry, machinery manufacturing, Building industry ,defense industry, and other fields Manufacturing industrial .valves and fittings,Instrument sliding bearing | |||||||||

The Chemical Composition of High Copper Alloys in ASTM

| Copper | Cu | Fe | Sn | Zn | Al | Pb | P |

| Alloy No | |||||||

| C19419 | 96.7min | 1.7-2.3 | .05-.18 | .10-.40 | -- | 0.02 | 0.03 |

| C19450 | Rem. | 1.5-3.0 | .8-2.5 | -- | -- | -- | .005-.05 |

| C19500 | 96.0min | 1.0-2.0 | .10-1.0 | 0.2 | 0.02 | 0.02 | .01-.35 |

| C19520 | 96.6min | .50-1.5 | -- | -- | -- | .01-3.5 | -- |

| C19700 | Rem. | .30-1.2 | 0.2 | 0.2 | -- | 0.05 | .10-.40 |

| C19710 | Rem. | .05-.40 | 0.2 | 0.2 | -- | 0.05 | .07-.15 |

| C19720 | Rem. | .05-.50 | 0.2 | 0.2 | -- | 0.05 | .05-.15 |

| C19750 | Rem. | .35-1.2 | .05-.40 | 0.2 | -- | 0.05 | .10-.40 |

| C19800 | Rem. | .02-.50 | .10-1.0 | .30-1.5 | -- | -- | .01-.10 |

| C19810 | Rem. | 1.5-3.0 | -- | 1.0-5.0 | -- | -- | 0.1 |

| C19900 | Rem. | -- | -- | -- | -- | -- | -- |

| C19910 | Rem. | .17-.23 | -- | -- | -- | -- | -- |

1.Grade

| GB | ISO | ASTM | JIS |

| H62 | CuZn40 | C27400 | C2740 |

| H63 | CuZn37 | C27200 | C2700 |

| H65 | CuZn35 | C26800 | C2680 |

| H68 | CuZn30 | C26000 | C2600 |

| H70 | CuZn30 | C26000 | C2600 |

| H80 | CuZn20 | C24000 | C2400 |

| H85 | CuZn15 | C23000 | C2300 |

| H90 | CuZn10 | C22000 | C2200 |

| H96 | CuZn5 | C21000 | C2100 |

| HPb59-1 | CuZn39Pb1 | C37000 | C3710 |

2. Chemical composition

| Grade | Composition | ||||

| Cu | Ni | Fe | Pb | Zn | |

| H62 | 60.5-63.5 | 0.5 | 0.15 | 0.08 | balance |

| H63 | 62.0-65.0 | 0.5 | 0.15 | 0.08 | balance |

| H65 | 63.5-68.0 | 0.5 | 0.1 | 0.03 | balance |

| H68 | 67.0-70.0 | 0.5 | 0.1 | 0.03 | balance |

| H70 | 68.5-71.5 | 0.5 | 0.1 | 0.03 | balance |

| H80 | 79.0-81.0 | 0.5 | 0.1 | 0.03 | balance |

| H85 | 84.0-86.0 | 0.5 | 0.1 | 0.03 | balance |

| H90 | 88.0-91.0 | 0.5 | 0.1 | 0.03 | balance |

| H96 | 95.0-97.0 | 0.5 | 0.1 | 0.03 | balance |

| HPb59-1 | 57.0-60.0 | 1 | 0.5 | 0.8-1.9 | balance |

3. Mechanical property

| Grade | Grade | Temper | External | Tensile Strength σb/MPa | Elongation(%) | |

| Diameter/mm | δ10 | δ5 | ||||

| (China) | (Japan) | more than | ||||

| H96 | C2100 | Y | 3-200 | 295 | - | - |

| M | 3-200 | 205 | 35 | 42 | ||

| H68 | C2600 | Y | 3.2-30 | 390 | 30 | 34 |

| M | 3-60 | 295 | 38 | 43 | ||

| H62 | C2740 | Y | 3.2-30 | 390 | 30 | 34 |

| M | 3-200 | 295 | 38 | 43 | ||

| HSn70-1 | Y | 3-60 | 345 | 30 | 34 | |

| M | 3-60 | 295 | 38 | 43 | ||

| HSn62-1 | C4621 | Y | 3-60 | 335 | 30 | - |

| M | 3-60 | 295 | 35 | - | ||

Certificate

Exhibition

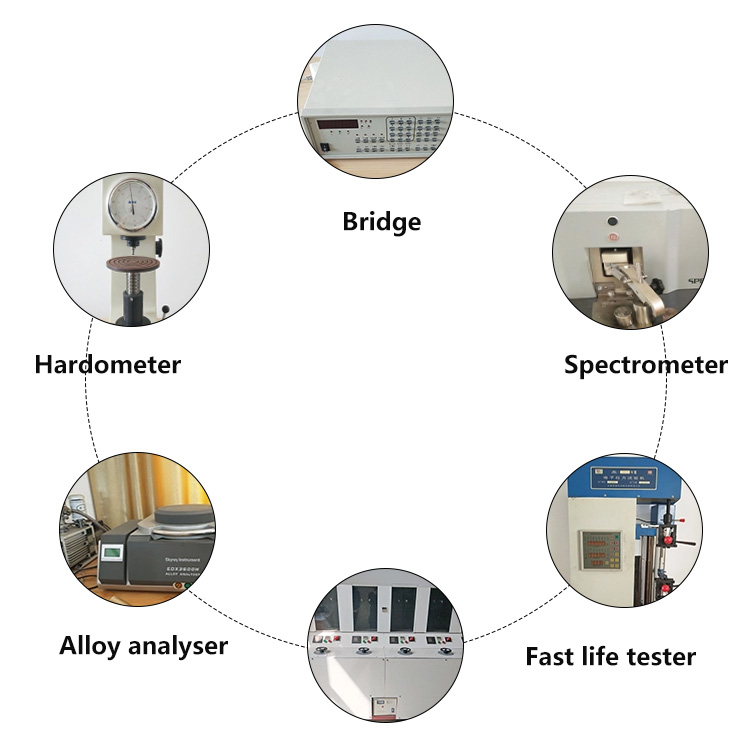

Inspection Equipment

Packaging process