Copper nickel alloy

| NC003,NC005,NC010,NC012,NC015,NC020,NC025,NC030,NC035,NC040,NC050 | |||||||||

| Properties/Materials | Main Chemical Composition |

Resistivity (200C μΩ.m) |

Max Working Temperature(℃) |

Tensile Strength (MPa) |

Elongation | Melting Point |

Density (g/cm3) |

||

| Ni | Mn | Cu | |||||||

| NC003(CuNi1) | 1 | / | rest | 0.03±10% | 200 | >210 | >25 | 1085 | 8.9 |

| NC005(CuNi2) | 2 | / | rest | 0.05±10% | 200 | >220 | >25 | 1090 | 8.9 |

| NC010(CuNi6) | 6 | / | rest | 0.10±10% | 220 | >250 | >25 | 1095 | 8.9 |

| NC012(CuNi8) | 8 | / | rest | 0.12±10% | 250 | >270 | >25 | 1097 | 8.9 |

| NC015(CuNi10) | 10 | / | rest | 0.15±10% | 250 | >290 | >25 | 1100 | 8.9 |

| NC020(CuNi14) | 14.2 | / | rest | 0.20±5% | 300 | >310 | >25 | 1115 | 8.9 |

| NC025(CuNi19) | 19 | / | rest | 0.25±5% | 300 | >340 | >25 | 1135 | 8.9 |

| NC030(CuNi23) | 23 | / | rest | 0.3±5% | 300 | >350 | >25 | 1150 | 8.9 |

| NC035(CuNi30) | 30 | / | rest | 0.35±5% | 350 | >400 | >25 | 1170 | 8.9 |

| NC040(CuNi34) | 34 | / | rest | 0.4±5% | 350 | >25 | 1180 | 8.9 | |

| NC050(CuNi44) | 44 | / | rest | 0.5±5% | 400 | >420 | >25 | 1200 | 8.9 |

| C70250 | |||||||||

| Articles,Chemical composition | |||||||||

| Articles | Chemical composition | ||||||||

| GB | UNS | EN | JIS | Cu% | Ni% | Si% | Mg% | ||

| - | C70250 | CuNi3SiMg | C7025 | Rem | 2.2-4.2 | 0.25-1.2 | 0.05-0.30 | ||

| Physical properties,fabrication properties | |||||||||

| physical properties | fabrication properties | ||||||||

| density g/cm3 | electrical conductivity %IACS | thermal conductivity W/(m.K) | modulus of elasticity GPa | specific heat J/(g.K) | cold-workability | machinability | electric plating property | hot dip tin plating property | weldability |

| 8.82 | 45 | 180 | 131 | 0.33 | good | less suitable | good | good | good |

| Mechanical properties | |||||||||

| Mechanical properties | |||||||||

| Status | hardness (HV) | Tension test | |||||||

| thickness(mm) | tensile strength(MPa) | yield strength MPa | elongation % | ||||||

| TR02 | 180-220 | 0.1-3.0 | 607-726 | ≥550 | ≥6 | ||||

| TM02 | 190-240 | 650-740 | ≥585 | ≥10 | |||||

| TM03 | 200-250 | 680-760 | ≥655 | ≥5 | |||||

| TM04 | 225-275 | 750-840 | ≥740 | ≥1 | |||||

| TM04S | 210-260 | 710-830 | ≥700 | ≥1 | |||||

We can cut the copper nickel alloy strip to the specific size depend on customer's requirements. They are packed with standard export package. There are kinds of types of products in our company, and we have the full stock of all types of grades and dimensions. It can meet the basic requirements of products in stock because of the surroundlogistics resources and timely delivery.

| C77000 | |||||||||||

| Articles,Chemical composition | |||||||||||

| Articles | Chemical composition | ||||||||||

| GB | UNS | EN | JIS | Cu% | Ni% | Zn% | |||||

| BZn18-26 | C77000 | CuNi18Zn27 | C7701 | 54-58 | 16.5-19.5 | Rem | |||||

| Physical properties,fabrication properties | |||||||||||

| Physical properties | fabrication properties | ||||||||||

| density g/cm3 | electrical conductivity %IACS | thermal conductivity W/(m.K) | modulus of elasticity GPa | specific heat J/(g.K) | cold-workability | machinability | electric plating property | hot dip tin plating property | weldability | corrosion | |

| 8.7 | 5 | 32 | 125 | 0.34 | excellent | suitable | excellent | excellent | good | excellent | |

| Mechanical properties | |||||||||||

| State | Hardness HV | Tension test | bending(in rolling direction)rest | bending(transverse to rolling direction)test | |||||||

| thickness mm | tensile strength MPa | yield strength MPa | elongation% | thickness mm | angles | ID | thickness | angles | ID | ||

| 1/2H | 150-210 | 0.1-0.7 | 540-655 | ≥390 | ≥8 | ≤1.6 | 180° | 150% of thickness | ≤0.5 | 180° | 300% of thickness |

| ≥0.71 | 540-655 | ≥390 | ≥11 | ||||||||

| H | 180-240 | 0.1-0.7 | 630-735 | ≥390 ≥500 | ≥4 | ≤1.6 | 180° | 200% of thickness | ≤0.5 | 180° | 400% of thickness |

| ≥0.71 | 630-735 | ≥500 | ≥6 | ||||||||

| EH | 210-260 | ≥0.1 | 705-805 | ≥600 | - | ≤1.6 | 90° | 300% of thickness | ≤0.5 | 90° | 600% of thickness |

| SH | 230-270 | ≥0.1 | 765-865 | ≥680 | - | - | - | - | - | - | - |

Typical application:Shields,Liquid crystal oscillators

| C75200 | ||||||||||

| Articles,Chemical composition | ||||||||||

| Articles | Chemical composition | |||||||||

| GB | UNS | EN | JIS | Cu% | Ni% | Zn% | ||||

| BZn18-18 | C75200 | CuNi18Zn20 | C7521 | 62-66 | 16.5-19.5 | Rem | ||||

| Physical properties,fabrication properties | ||||||||||

| Physical properties | fabrication properties | |||||||||

| density g/cm3 | electrical conductivity %IACS | thermal conductivity W/(m.K) | modulus of elasticity GPa | specific heat J/(g.K) | cold-workability | machinability | electric plating property | hot dip tin plating property | weldability | corrosion |

| 8.73 | 6 | 32 | 125 | 0.34 | excellent | suitable | excellent | excellent | good | excellent |

| Mechanical properties | ||||||||||

| State | Hardness HV | Tension test | bending test | |||||||

| Thickness mm | Tensile strength MPa | elongation % | thickness | angles | ID | |||||

| 0 | - | 0.1-5.0 | ≥375 | ≥20 | ≤1.6 | 180° | sticking closely | |||

| 1/2H | 120-180 | 0.1-5.0 | 440-570 | ≥5 | ≤1.6 | 180° | 100% of thickness | |||

| ≤0.5 | 200% of thickness | |||||||||

| H | 150-210 | 0.1-0.15 | 540-640 | - | ≤1.6 | 180° | 200% of thickness | |||

| >0.15-5.0 | ≥3 | ≤0.5 | 400% of thickness | |||||||

| EH | ≥185 | 0.1-5.0 | ≥610 | - | - | - | - | |||

Typical application:

Shields,Liquid crystal oscillators,pressing parts

| C75400 | ||||||||||

| Articles,Chemical composition | ||||||||||

| Articles | Chemical composition | |||||||||

| GB | UNS | EN | JIS | Cu% | Ni% | Zn% | ||||

| BZn15-20 | C75400 | CuNi15Zn20 | C7541 | 60-64 | 12.5-15.5 | Rem | ||||

| Physical properties,fabrication properties | ||||||||||

| Physical properties | fabrication properties | |||||||||

| density g/cm3 | electrical conductivity %IACS | thermal conductivity W/(m.K) | modulus of elasticity GPa | specific heat J/(g.K) | cold-workability | machinability | electric plating property | hot dip tin plating property | weldability | corrosion |

| 8.7 | 6 | 32 | 135 | 0.34 | excellent | suitable | excellent | excellent | good | excellent |

| Mechanical properties | ||||||||||

| State | Hardness HV | Tension test | bending test | |||||||

| Thickness mm | Tensile strength MPa | elongation % | thickness | angles | ID | |||||

| 0 | - | 0.1-5.0 | ≥355 | ≥20 | ≤1.6 | 180° | sticking closely | |||

| 1/2H | 110-170 | 0.1-5.0 | 410-540 | ≥5 | ≤1.6 | 180° | 100% of thickness | |||

| ≤1.6 | 200% of thickness | |||||||||

| >0.15-5.0 | ≥490 | ≥3 | ||||||||

The free cutting white brass with lower integrated cost, higher cost performance, superior cutting performance and processing efficiency is widely used in the nibs, glasses accessories and instrument accessories manufacturing.

Categories: Nickel Silver Alloys Material(monel wire)

Name: Pb-Zn Nickel Silver

Number: Cu43Ni12Zn38Mn5Pb2,C79400,C79200

Feature:

Integrated low-cost: compared with the same lead-copper-nickel alloy with low-density 5%, 5% less material cost, integrated low-cost 10 percent more;

Superior cutting performance, processing more efficient;

Good weldability;

Resistance to Moldova, and good corrosion resistance.

| Article | Specification | Performance | Usage | |||

| ASTM/CDA | DIN | JIS | GB/QB | DIN | ||

| C79400 | Cu43Ni12 | — | BZn12-6-1.5 | 0.8mm-10mm(Special-Shaped) | Excellent corrosion-resistance,elasticity, | Suitable to be made into ball point pen tips, glasses accessories,frame parts,instrument parts,etc. |

| Zn38Mn5Pb2 | Welding performance and high strength | |||||

| C79200 | - | - | BZn10-2-2 | |||

Relevant Property

| Chemical Composition | ||||||||||

| Alloy | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe | Total Impurity |

| ≥ | ||||||||||

| N2 | 99.98 | 0.001 | 0.003 | 0.002 | 0.005 | 0.003 | 0.001 | 0.001 | 0.007 | 0.02 |

| N4 | 99.9 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 | 0.1 |

| N6 | 99.5 | 0.06 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 | 0.5 |

| N8 | 99 | 0.15 | 0.15 | 0.2 | 0.2 | 0.1 | 0.015 | - | 0.3 | 1 |

| DN | 99.35 | 0.06 | .02-.10 | 0.05 | .02-.10 | .02-.10 | 0.005 | 0.002 | 0.1 | 0.35 |

| NY1 | 99.7 | 0.1 | 0.1 | - | 0.02 | 0.1 | 0.005 | - | 0.1 | 0.3 |

| NY2 | 99.4 | .01-.10 | 0.1 | - | - | - | .002-.01 | - | 0.1 | 0.6 |

| NY3 | 99 | 0.15 | 0.2 | - | 0.1 | 0.1 | 0.005 | - | 0.25 | 1 |

| NMn3 | Balance | 0.5 | 0.3 | 2.30-3.30 | 0.3 | 0.1 | 0.03 | 0.01 | 0.65 | 1.5 |

| NMn5 | Balance | 0.5 | 0.3 | 4.60-5.40 | 0.3 | 0.1 | 0.03 | 0.02 | 0.65 | 2 |

| NiSi3 | Balance | - | 43134 | .05-.07 | 0.05 | - | 0.02 | 0.002 | 0.1 | - |

| NCr10 | Balance | - | .05-.06 | .01-.2 | 0.05 | - | 0.02 | 0.002 | 0.1 | - |

| Surface | ||||||||||

| Surface Finish | Definition | Application | ||||||||

| 2B | Those finished, after cold rolling, by heat treatment, picking or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry,Construction material, Kitchen utensils. | ||||||||

| BA | Those processed with bright heat treament after cold rolling. | Kitchen utensils, Electric equipment, Building construction. | ||||||||

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. | ||||||||

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. | ||||||||

| HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building construction. | ||||||||

| NO.1 | The surface finished by heat treament and picking or processes corresponding there to after hot rolling. | Chemical tank, pipe. | ||||||||

Certificate

Exhibition

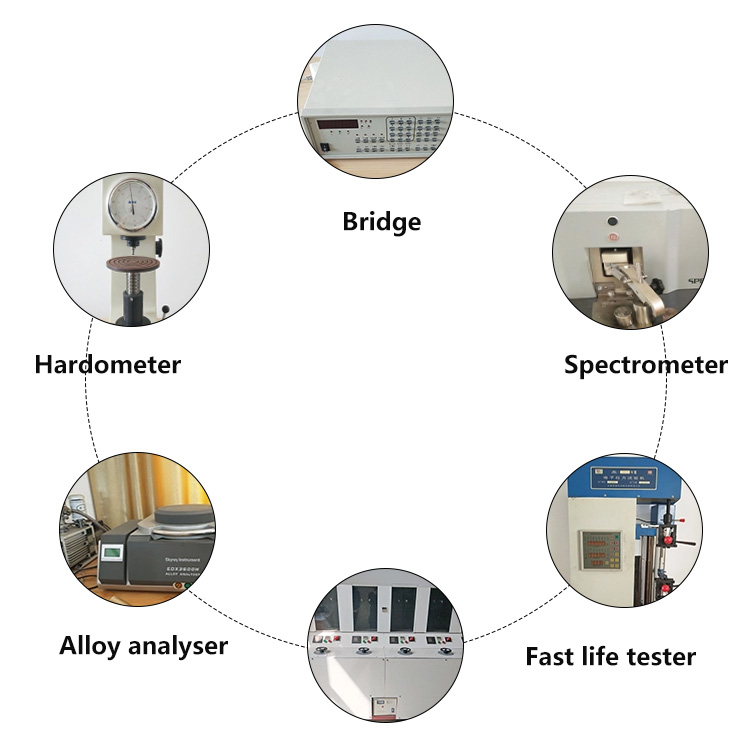

Inspection Equipment

Packaging process