Nickel-plated copper wire is a layer of nickel that is concentrically applied to the copper core. It has excellent oxidation resistance and corrosion resistance, as well as high temperature resistance. It can prevent re-oxidation of the copper wire and is degraded by surface oxidation. The coating reduces high frequency losses in high frequency applications.

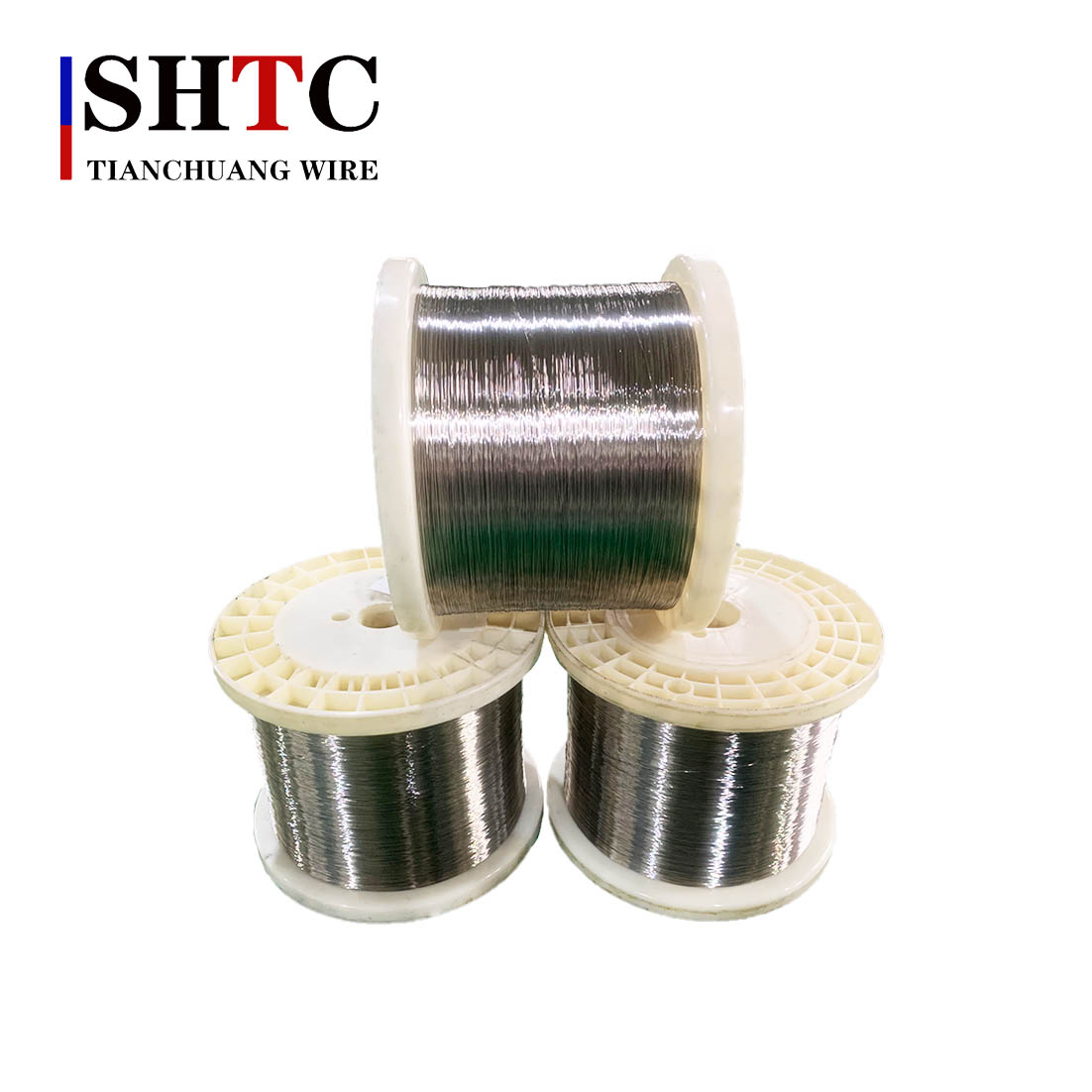

There are nickel-plated soft copper wire and nickel-plated hard copper wire. The diameter is 0.10 mm to 2.0 mm, and the nickel plating layer is continuously and firmly attached to the surface of the conductor. Suitable for stranded wires, high temperature conductors and applications with high chemical requirements, high frequency applications, etc.

When using high temperature lead wire, one aspect that users should keep in mind is the way the cables handle temperatures. At high temperatures, copper wires will oxidize and you may not realize or see the damage occurring with naked eyes. To help prevent damage and prolong the service life of the cables, they are coated with thermal resistance substances.

Among the commonly used plating materials for high temperature lead wires are tin, silver, and nickel. For instance, Radix Wire PFA High Temperature Lead Wire 250C 300V and 600V is coated with nickel to reduce corrosion and ensure durability.

Characteristics

1. Nickel-plated copper wire is made of soft copper as the core material, and a uniform nickel layer is deposited on the surface by electroplating.

2. The nickel-plated copper wire has the strength and softness of mild copper and the corrosion resistance of nickel.

3. It can be used as an indispensable element in electronics as an alternative to expensive bare nickel wire.

Post time: Nov-13-2020