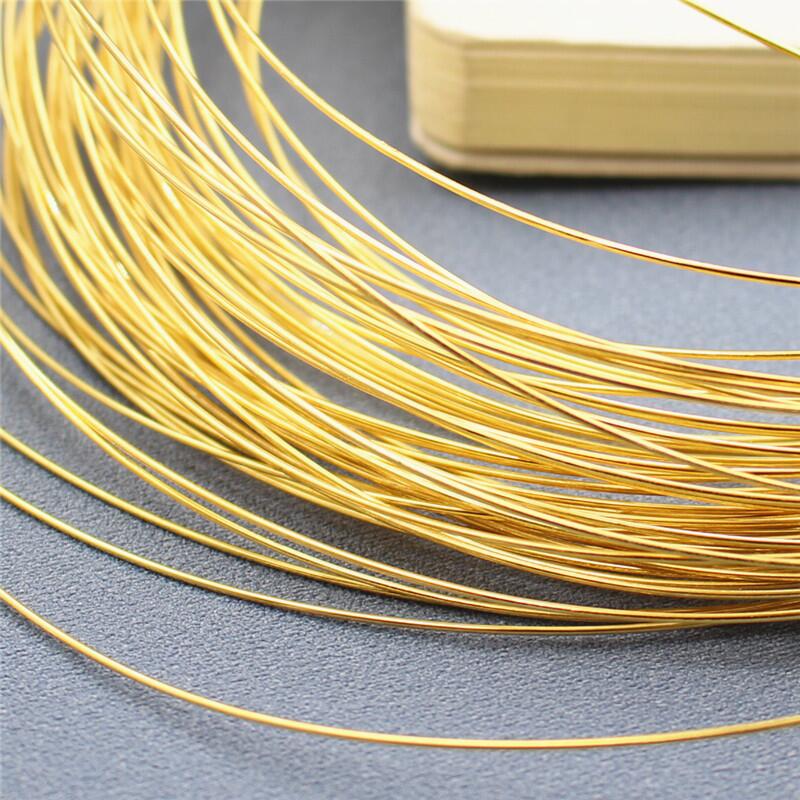

We've heard about some plated wires in specialized fields like industry or aviation. But do you really know about that?

First let me show you about electroplating.

WHAT IS ELECTROPLATING?

Electroplating is the process of coating one metal or metal object with a very thin layer of another metal, typically by applying a direct electric current. This partially dissolves the metals and creates a chemical bond between them. The coating applied by electroplating is usually around 0.0002 inches thick.

By creating a chemical bond, the plating is a permanent addition to the surface of the base metal. This means that it will not naturally fall off or separate. However, plating can be worn off over months and years of use and wear.

Because this top layer is so thin, it has very specific uses. Some metals are used as a coating, because they give added protection from rust, damage or corrosion.

Then let me introduce three more familiar types of electroplated wires.

Post time: Oct-21-2020